- Technology Driven, High Performance Fasteners

- Sonipat, Haryana India

- sales@bigboltnut.com

ZINC FLAKE COATING

Zinc-flake coatings are sacrificial coatings which contain zinc and/or aluminium elements that oxidize sacrificially to ensure the substrate of to which they are applied remains corrosion free. These coating systems were designed for automotive and industrial parts that require greater protection than what standard paint and other coating systems can supply. Zinc-flake coatings are used to protect non-flexing or rarely-flexing parts like brake rotors, drums and callipers; brake lines and hose clamps; fuel tanks and filler pipes; mufflers; the underside of hoods; clips, fasteners, springs and stampings; seat belt components and door lock components…and pretty much anything else that comes in contact with the elements and can survive a 450-degree curing cycle. These coatings can also prevent galvanic corrosion as a result of dissimilar metals coming in contact with each other. This is an extremely beneficial attribute in today’s age of light-weighting vehicles where aluminium components are more prevalent.

The purpose of the specification is to provide requirements for a thin film zink flake coating to provide corrosion protection.This coating is primarily used on fasteners, But is also appropriate for other small parts made from ferrous material.

ISO 10683 : Fasteners-Non electrolytic ally applied Zink flake coating

ISO 1463 : Metallic and Oxide coatings- Measurement of coating thickness

ISO 9227 : Corrosion test in artificial atmosphere-Salt

spray test

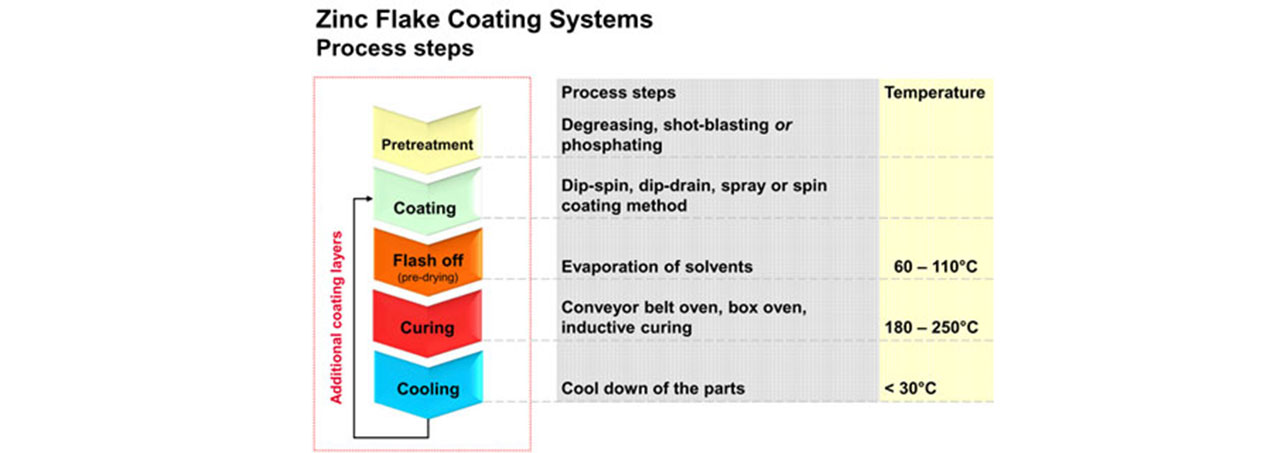

Zink flake coating system are produced bit applying a Zink flake dispersion to the surface of the steel part, usually with the addition of aluminium flakes, in a suitable medium. Under the influence of heat (curing), bonding amongst flakes and also between flakes and substrate is generated, thus forming an inorganic surface coating sufficiently electrically conducting to ensure catholic protection.

Prior to coating, the parts surface need to be pre-treated. Pickling with acids (sulfuric & hydrochloric) Produces atomic hydrogen and can penetrate into the steel structure and make it brittle. Typical cleaning processes with an alkaline aqueous solution to remove oil, dirt from the surface of the part.

Chemical Used : steelex k 20

Concentration : 80-100 gm/ltr

Temperature : 70-90'C

Dip time : 4-5 mins

Blasting process is used for removing scaling and rust through the mechanical action of steel balls which are fired at the parts inside a chamber of shot blasting machine.

Shot Size : 0.2 mm, grade S70

Blasting Time : 7-9 min

Loading : Less than 200 kg

Paint mix is the process where the coating agent is prepared according to grade, colour and properties.

Solid Content : up to 36%

PH : 7.86

Sg : 1.27

Viscosity : 13 Sec

Tempearure : 22⁰ C

After surface preparation it comes to the coating process. Mounted on a rack the parts get sprayed with the zink flake material ( Auto spray Process) or placed into a container, they get dipped and spun ( Dip Spinning Process). The coating material form a liquid uniform layer on the parts surface in order to develop the excellent properties of zink flake coating.

Air pressure : 2.5 - 6 kg/cm2

Gun Paint pre. : 1 - 2 kg/cm2

Pump Pressure : 1 - 2 kg/cm2

Loading : 4 Nos.

Preheating is done to get better result of coating and is done on a conveyor oven for a given time period and temperature.

Temperature : 80 - 100⁰C

Speed : 140 - 170 mm/min

The coated parts have to be cured inside on oven at a controlled temperature for set period. This configuration is dependent on the coating material and the product manufacturer.

Temperature : 300 - 315⁰C

Speed : 140 - 170 mm/min

This process is done to get back the product to its normal temperature with better appearance of coating and the coating properties.

Cooling Time : 20-25 min

|

Process Phase |

Parameters to be Check |

|

Layer Thickness |

According to ISO 10683 |

|

Appearance |

According to ISO 10683 |

|

Coating Weight (part<2kg) |

According to ISO 10683 |

|

Adhesion test |

According to ISO 10683 |

|

NSS testing |

According to ISO 10683 |

|

NSS testing(Baked to150'C for 3 Hrs) |

According to ISO 10683 |

|

Cathodic Protection Test |

According to ISO 10683 |

Photographs of the sample parts, before inspection must be included. The photograph or image Caption must clearly include the part reference, measured values and exposure conditions.

The technical staff member and the laboratory manager must sign and certify the results presented in the report at the end of the document