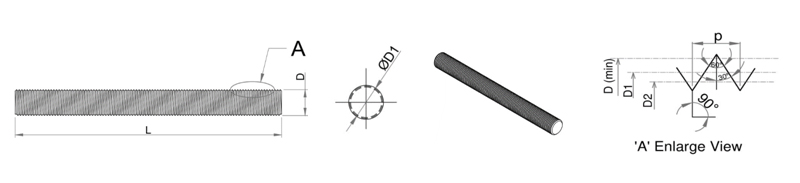

DIN 2510 Bolting components and connections with expansion shank are suitable for use at elevated temperatures with high pressure and with optimum Charpy Notch Impact strength for cryogenic applications. Screw connections with reduced shank in DIN 2510 standard are primarily used in situations where bias voltage is applied and where durability of screw connections has to be extensively secured under varying mechanical and thermal stress environments. DIN 2510 Reduced Shank Bolts show good durability when combined with high temperature resistant material in accordance with EN 10269-specification material. The bias drop is quite low and hence it contributes significantly to the loosening of the screw connections during working operation by creep factors of the material, settling in the force-transmitting surfaces of the connection and the strained parts, and by bending the threads.

When designing expansion bolts and expansion bolts, the following points should be noted:

a) The minimum expansion shaft length should be Double or four times the thread diameter, in order to obtain sufficient elasticity.

b) The

ratio of thread core diameter to shank diameter should be about 1:1 in view of the load capacity and elasticity of the screw.

c) The transition angle

between the expansion shaft and the thread should be relatively small. This results in a favourable flow of force and a better load distribution in the screwed thread.

|

d1 |

d2 |

d3 |

d7 |

FORM L |

FORM K / KU |

FORM Z / ZU |

r |

SW |

z1 max |

z2 |

FORM KU |

FORM ZU |

|

b1 |

z |

|||||||||||

|

M12 |

8,5 |

8 |

8 |

20 |

13 |

27 |

10 |

7 |

1,75 |

4 |

11 |

7 |

|

M16 |

12 |

12 |

12 |

23 |

16 |

31 |

10 |

10 |

2 |

5 |

14 |

8 |

|

M20 |

15 |

14 |

13 |

28 |

20 |

36 |

10 |

11 |

2,5 |

6 |

16 |

9 |

|

M24 |

18 |

14 |

16 |

32 |

24 |

42 |

16 |

11 |

3 |

6 |

17 |

8 |

|

M27 |

20,5 |

18 |

18 |

35 |

27 |

47 |

16 |

13 |

3 |

6 |

19 |

10 |

|

M30 |

23 |

18 |

21 |

39 |

30 |

50 |

16 |

13 |

3,5 |

6 |

19 |

12 |

|

M33 |

25,5 |

25 |

24 |

42 |

33 |

53 |

16 |

22 |

3,5 |

9 |

21 |

14 |

|

M36 |

27,5 |

25 |

26 |

45 |

36 |

57 |

20 |

22 |

4 |

9 |

23 |

14 |

|

M39 |

30,5 |

28 |

30 |

48 |

39 |

60 |

20 |

24 |

4 |

10 |

23 |

14 |

|

M42 |

32,5 |

28 |

32 |

52 |

42 |

64 |

20 |

24 |

4,5 |

10 |

24 |

15 |

|

M45 |

35,5 |

32 |

34 |

55 |

45 |

66 |

20 |

27 |

4,5 |

11 |

25 |

15 |

|

M48 |

37,5 |

32 |

37 |

58 |

48 |

70 |

20 |

27 |

5 |

11 |

26 |

19 |

|

M52 |

41 |

36 |

40 |

62 |

52 |

74 |

20 |

30 |

5 |

12 |

26 |

18 |

|

M56 |

44 |

40 |

45 |

— |

56 |

79 |

25 |

32 |

5,5 |

13 |

28 |

19 |

|

M64 |

51 |

42 |

52 |

— |

64 |

88 |

25 |

36 |

6 |

14 |

28 |

20 |

|

M72x6 |

58,5 |

50 |

56 |

— |

72 |

95 |

25 |

41 |

6 |

15 |

28 |

20 |

Note :

FORM L - Long thread, FORM K - Short thread, FORM KU - Short thread, FORM Z - Long thread, FORM ZU - Long thread